Introduction to Subminiature-D Coaxial Feedthroughs

subminiature-d coaxial feedthroughs, often abbreviated as Sub-D feedthroughs, are a vital component in modern electrical and electronic systems. These devices are specifically designed to allow coaxial signals to pass seamlessly through a barrier, such as a vacuum chamber or an environmental enclosure, without compromising the integrity of the seal. Their versatility makes them indispensable in various industries, from telecommunications to aerospace.

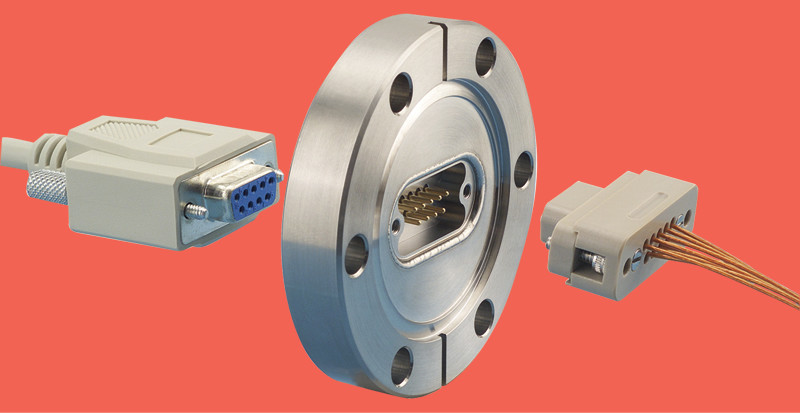

To appreciate the importance of Subminiature-D coaxial feedthroughs, it’s essential to understand their structure, functionality, and application. These components consist of a coaxial connector integrated into a Subminiature-D (D-sub) interface. This design combines the shielding and signal integrity benefits of coaxial connectors with the compact, multi-pin layout of D-sub connectors, offering a unique solution for space-constrained and high-performance applications.

From facilitating high-frequency signal transmission to providing robust sealing solutions, Sub-D coaxial feedthroughs play a pivotal role in ensuring the efficiency and reliability of modern systems. This article delves deep into their features, applications, and considerations for selecting the right feedthrough for specific needs.

The Anatomy of Subminiature-D Coaxial Feedthroughs

Key Components

Subminiature-D coaxial feedthroughs comprise several essential subminiature-d coaxial feedthroughs elements:

- Coaxial Connector:

- At the heart of the feedthrough is the coaxial connector, which ensures high-frequency subminiature-d coaxial feedthroughs signal integrity by maintaining consistent impedance.

- Coaxial connectors are surrounded by shielding to reduce electromagnetic interference (EMI) and maintain signal fidelity.

- D-Sub Interface:

- The D-sub interface provides the multi-pin connector design commonly used in electronic equipment.

- This interface allows multiple coaxial lines to be integrated into a single connector, subminiature-d coaxial feedthroughs optimizing space and reducing installation complexity.

- Sealing Mechanism:

- A sealing mechanism, such as an O-ring or hermetic seal, ensures environmental isolation. This feature is crucial for maintaining vacuum conditions or protecting sensitive electronics from external contaminants.

- Housing and Insulation:

- The housing encases the components and provides mechanical subminiature-d coaxial feedthroughs stability.

- Insulation materials prevent electrical shorts and maintain signal isolation.

Variations and Configurations

Subminiature-D coaxial feedthroughs are available in several configurations to suit diverse requirements:

- Single and Multi-Channel: Depending on the application, feedthroughs may support a single coaxial line or multiple lines.

- Frequency Range: Different models cater to varying frequency ranges, ensuring optimal performance for specific signals.

- Sealing Types: Hermetic and non-hermetic options are available, depending subminiature-d coaxial feedthroughs on the environmental demands.

Applications of Subminiature-D Coaxial Feedthroughs

Telecommunications and Networking

One of the primary uses of Sub-D coaxial feedthroughs is in telecommunications and networking. subminiature-d coaxial feedthroughs These feedthroughs enable high-speed data transmission by providing low-loss, interference-free connections for coaxial cables. For example:

- Base Stations: They are used in cellular base stations to connect internal components with external antennas.

- Network Equipment: Routers, switches, and other networking gear rely on these feedthroughs to handle high-frequency signals.

The ability to support multiple coaxial lines in a compact form factor makes Sub-D feedthroughs subminiature-d coaxial feedthroughs ideal for crowded telecom environments.

Aerospace and Defense

In aerospace and defense, reliability and durability are paramount. Subminiature-D coaxial feedthroughs meet these demands with their robust design and sealing capabilities. Applications include:

- Avionics Systems: Ensuring signal integrity in the complex wiring of aircraft and spacecraft.

- Radar Systems: Providing connections for high-frequency radar signals without signal degradation.

These feedthroughs’ hermetic sealing capabilities make them suitable for use in pressurized or vacuum environments, which are common in aerospace applications.

Research and Industrial Applications

Laboratories and industrial setups frequently use Sub-D coaxial feedthroughs for specialized equipment. Examples include:

- Vacuum Chambers: Maintaining vacuum conditions while allowing coaxial signals to pass subminiature-d coaxial feedthroughs through.

- Medical Equipment: Connecting imaging devices and diagnostic machines that require high-frequency signal transmission.

Their versatility and reliability make them a staple in advanced research and industrial settings.

Advantages of Subminiature-D Coaxial Feedthroughs

Compact Design

The integration of multiple coaxial lines into a single D-sub connector saves significant space compared to using individual coaxial connectors. This compact design is especially beneficial in systems where space is at a premium.

High Signal Integrity

The coaxial structure ensures minimal signal loss and maximum interference rejection. subminiature-d coaxial feedthroughs This feature is critical in applications requiring high-frequency signal transmission.

Robust Sealing

Hermetic sealing options allow these feedthroughs to maintain environmental isolation, making subminiature-d coaxial feedthroughs them suitable for harsh or sensitive environments.

Versatility

With a variety of configurations available, Sub-D coaxial feedthroughs can be tailored to meet subminiature-d coaxial feedthroughs specific application requirements, from low-frequency signals to gigahertz-range frequencies.

Selecting the Right Subminiature-D Coaxial Feedthrough

Frequency Requirements

The frequency range of the signals to be transmitted is a critical factor in feedthrough selection. Higher-frequency applications require feedthroughs with precision-engineered coaxial connectors to maintain signal integrity.

Environmental Conditions

Consider the operating environment:

- Vacuum or Pressurized Enclosures: Hermetic sealing is necessary to prevent leaks.

- Temperature Extremes: Ensure the feedthrough’s materials can withstand the expected temperature range.

Connector Configuration

Choose a configuration that matches your system’s needs:

- Number of Channels: Determine the number of coaxial lines required.

- Connector Type: Ensure compatibility with the mating connectors.

Cost and Durability

While cost is always a consideration, prioritize durability and performance to avoid premature failures and additional expenses in critical applications.

Installation and Maintenance

Proper Installation Techniques

To maximize the performance and lifespan of Sub-D coaxial feedthroughs, proper installation is crucial:

- Torque Settings: Follow the manufacturer’s specifications for tightening connectors to avoid damage.

- Alignment: Ensure connectors are properly aligned to prevent misconnection and signal loss.

Routine Maintenance

Regular maintenance can extend the service life of feedthroughs:

- Inspect Seals: Check for wear or damage to hermetic seals.

- Clean Contacts: Remove dirt and oxidation from connectors to maintain good electrical contact.

- Test Signal Integrity: Periodically verify the performance using appropriate testing equipment.

Innovations and Future Trends

As technology advances, Subminiature-D coaxial feedthroughs continue to evolve. Innovations include:

- Higher Frequency Ranges: Accommodating emerging technologies like 5G and millimeter-wave communications.

- Improved Materials: Utilizing advanced composites for better durability and performance.

- Miniaturization: Developing even smaller feedthroughs for compact and lightweight devices.

These advancements will ensure that Sub-D coaxial feedthroughs remain a cornerstone of high-frequency signal transmission in diverse industries.

Conclusion

Subminiature-D coaxial feedthroughs are indispensable in modern engineering and technology. Their unique combination of compactness, high signal integrity, and robust sealing makes them suitable for a wide range of applications, from telecommunications to aerospace.

Understanding their anatomy, advantages, and application areas can help engineers and technicians make informed decisions when integrating these components into their systems. With ongoing innovations, Sub-D coaxial feedthroughs are poised to meet the challenges of tomorrow’s high-frequency and high-performance requirements.